One major challenge for manufacturers around the world is the process of research & developement (or “R&D) which requires “prototyping”. In the past, we would design a part and draw technical pictures of it, then send the design to a factory where they would develope a “prototype” (or “test”) of the part. They would send the prototype back to the customer who would evaluate the part and either confirm the design, or make modifications. This could easily go on for multiple revisions, each time costing hundreds or thousands of dollars and weeks or months of delay.

Thankfully, technology now allows us to do “rapid prototyping” with 3D printing technology. We can develope an idea, draw the design in a 3D rendering program on the computer, then send the design to a 3D extruding printer, which melts and extrudes various types of plastics to build a 3D model of the object. The biggest advance is in the time, what took months or even years in the past, can now be done in hours.

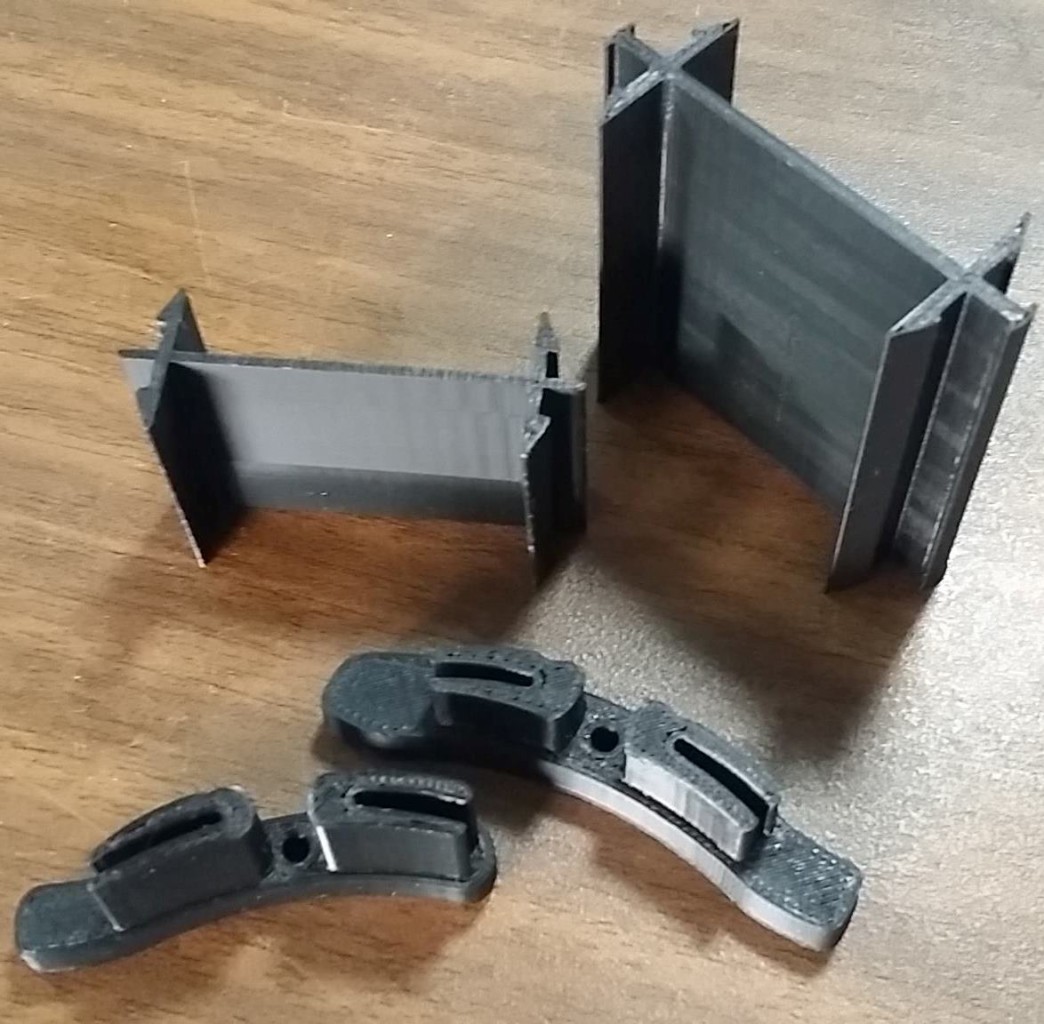

We recieved the MakerGear M2 3D printer mid January, and have already been successful in developing several new prototypes for new product parts and improvements for older products.