Peters Glass Shop is proud to announce the installation of the first glass tempering furnace in Belize. Tempered glass represents a unique challenge to discerning buyers, as all cutting and modification of the glass must be completed prior to the tempering process. This means that when importing, the cost is very high, logistics is very challenging, and there is zero margin for error. Having the ability to temper glass right here in Belize is very exciting. Stop buy our factory in Spanish Lookout today, or email us or call us for a price quote for your custom project.

New office complete!

We have been working hard over the past few months to build a new office & showroom. The office is now complete and we have moved in and we are ready to serve you. Please stop in for a visit.

You will find that more work is being done as we continue to prepare the new office to display many of our products, please bear with us through these disruptions.

We are also continuing work on our building expansion project. This will expand our facility from 33,000sqft to almost 70,000sqft.

We are hard are work expanding our factory in Spanish Lookout to serve you better.

We have recently begun working on an infrastructure expansion project which will double the size of our facility. The immense demand for our high quality doors & windows keeps us on our toes, and we are growing in response to this constant demand.

In addition, we have begun work on a new showroom to provide you a better, more informational shopping experience. We will be able to display more of our products, and you will be better suited to select products that will best suit your individual needs.

While these upgrades are under construction, we do ask your patience and apologize for any inconvenience this may cause. We anticipate the office will be complete by the end of this year, and the factory expansion will be completed in the spring of 2019.

A quick video to show you new technology in action at Peters Glass Shop.

3D Printing at Peters Glass Shop

A quick video to show you new technology in action at Peters Glass Shop. Serving Belize since 2003.

Posted by Peters Glass Shop on Tuesday, December 13, 2016

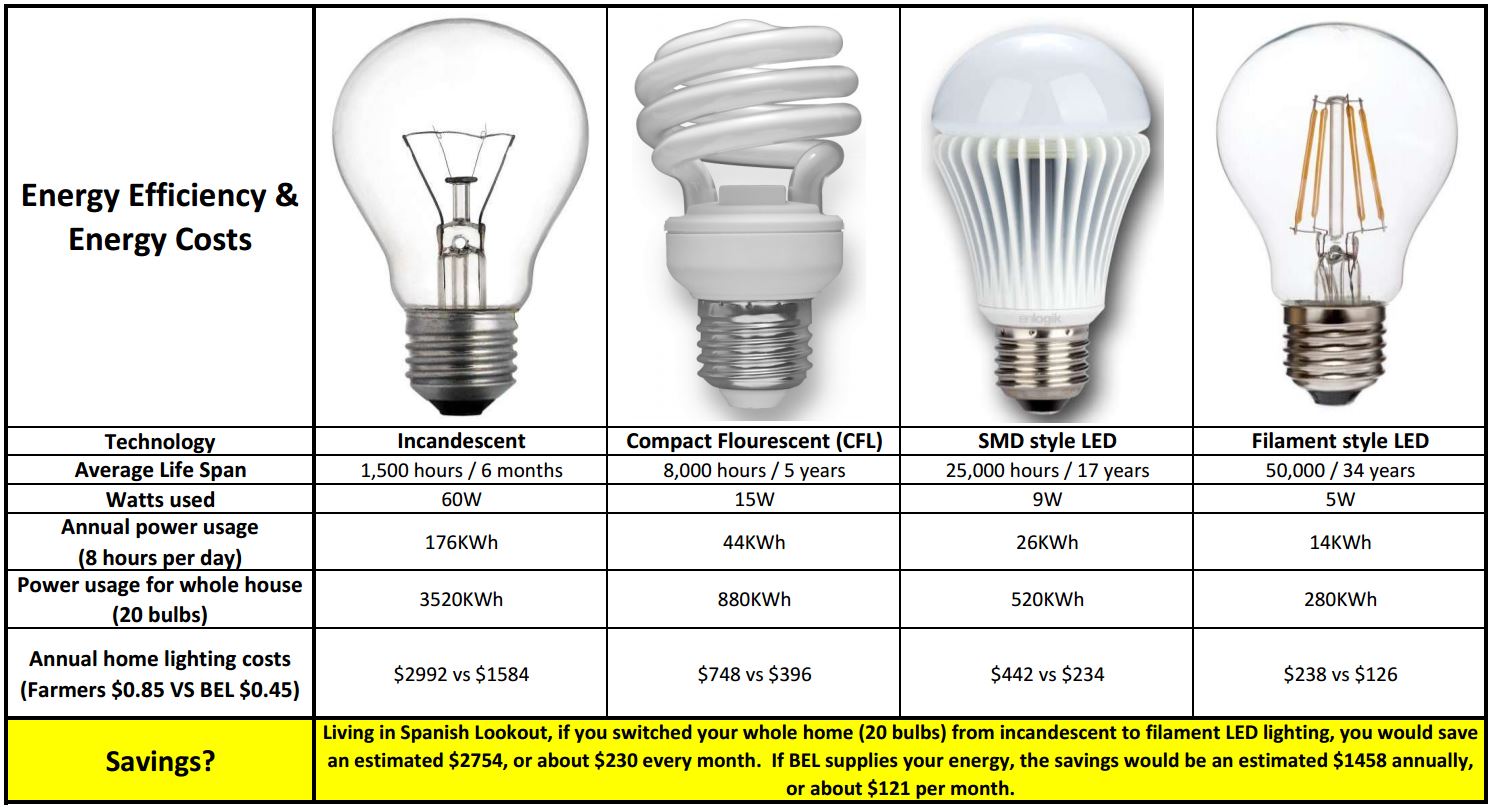

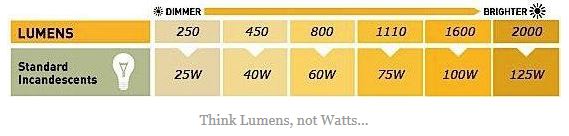

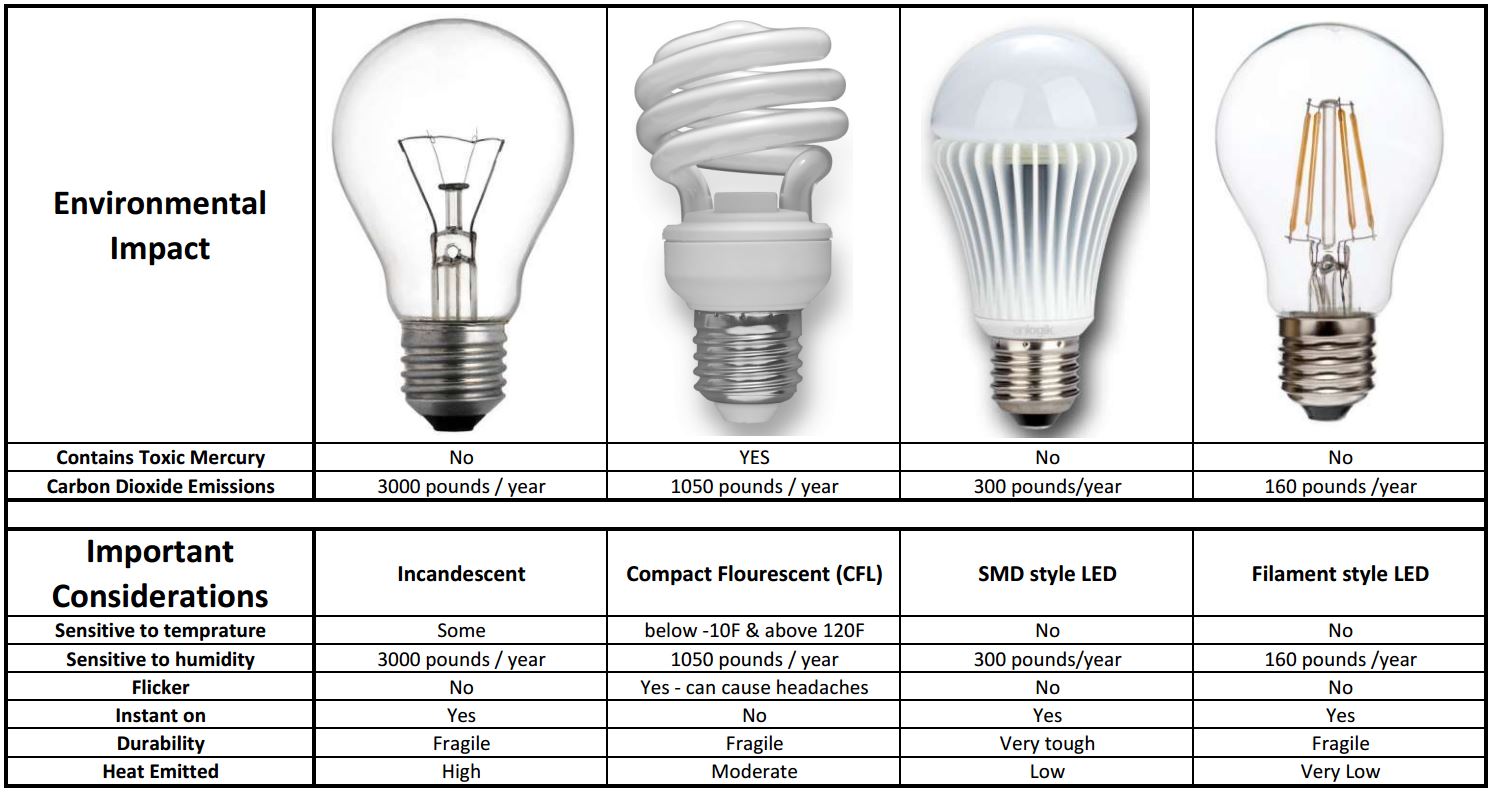

How much money can LED light bulbs save you in Belize?

New technology in action!

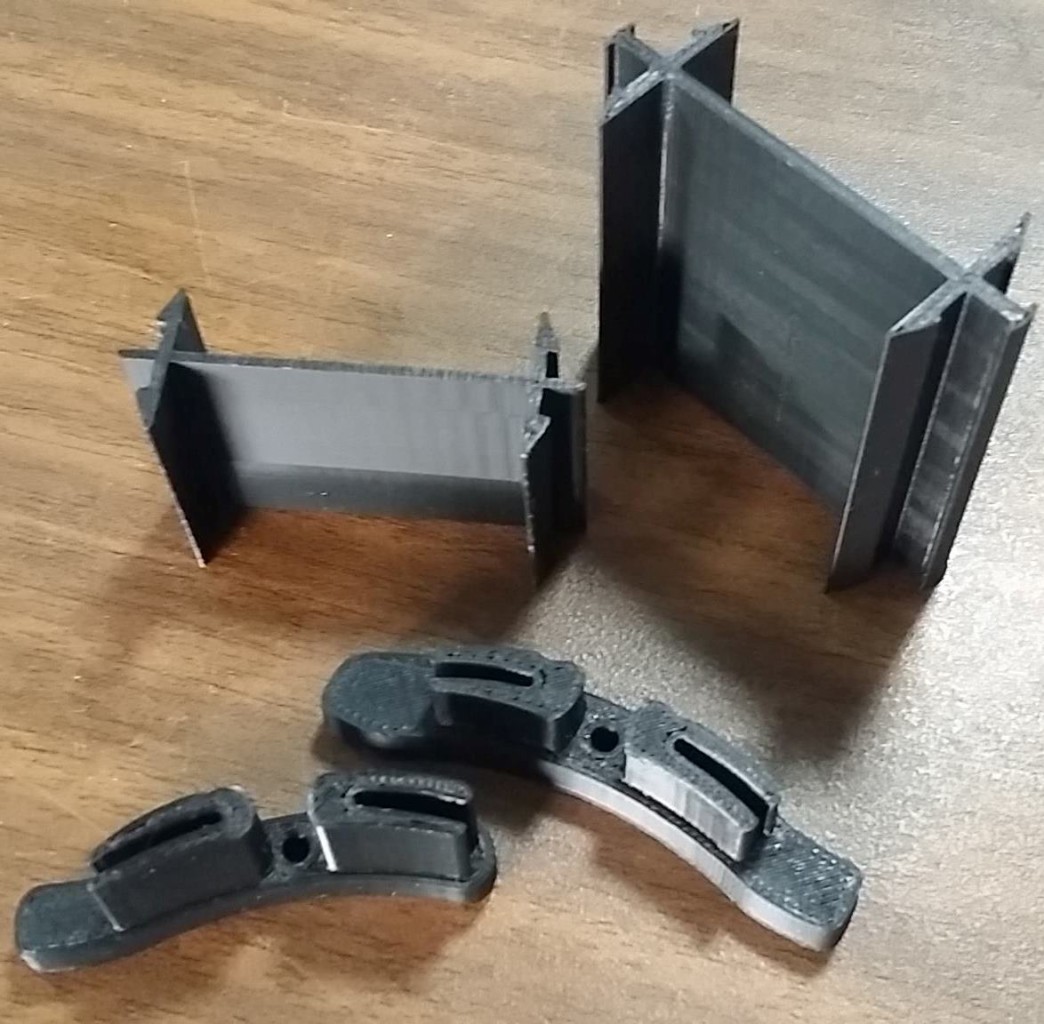

One major challenge for manufacturers around the world is the process of research & developement (or “R&D) which requires “prototyping”. In the past, we would design a part and draw technical pictures of it, then send the design to a factory where they would develope a “prototype” (or “test”) of the part. They would send the prototype back to the customer who would evaluate the part and either confirm the design, or make modifications. This could easily go on for multiple revisions, each time costing hundreds or thousands of dollars and weeks or months of delay.

Thankfully, technology now allows us to do “rapid prototyping” with 3D printing technology. We can develope an idea, draw the design in a 3D rendering program on the computer, then send the design to a 3D extruding printer, which melts and extrudes various types of plastics to build a 3D model of the object. The biggest advance is in the time, what took months or even years in the past, can now be done in hours.

We recieved the MakerGear M2 3D printer mid January, and have already been successful in developing several new prototypes for new product parts and improvements for older products.